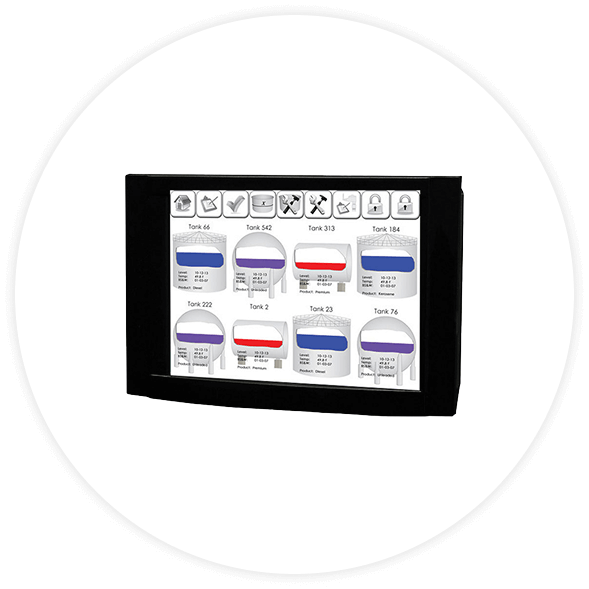

Choose the MCG 3630 when you need a centralized, touchscreen tank monitor that displays level, temperature, BS&W, and inventory data across multiple tanks with flexible protocols and easy configuration.

Choose the MCG 7030 for an independent, self-testing high-level alarm system that continuously monitors alarm probes, ensures regulatory compliance, and delivers reliable alarm visibility, even without a gauging system.

Remote or unmanned sites requiring clear local visualization.