A displacer switch is a mechanical level control device that detects changes in liquid level using buoyancy principles. Unlike float switches or electronic sensors, displacer switches rely on Archimedes’ principle — as liquid level changes, the buoyant force acting on the displacer changes.

This movement triggers a magnetically coupled snap-action switch to open or close an electrical contact, providing precise, repeatable control for level alarm, pump control, or shutdown functions.

Because the displacer and magnetic assembly are mechanically isolated from the process, these switches offer long-term reliability without recalibration, drift, or electronic interference — ideal for harsh, pressurized, or hazardous environments.

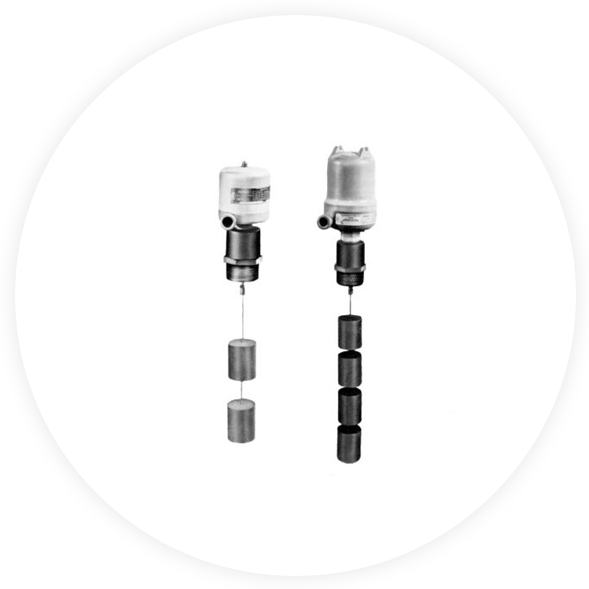

The Omnitrol 610 / 710 Series uses graphite displacers that ensure precise, repeatable switching without external power in extreme product conditions.

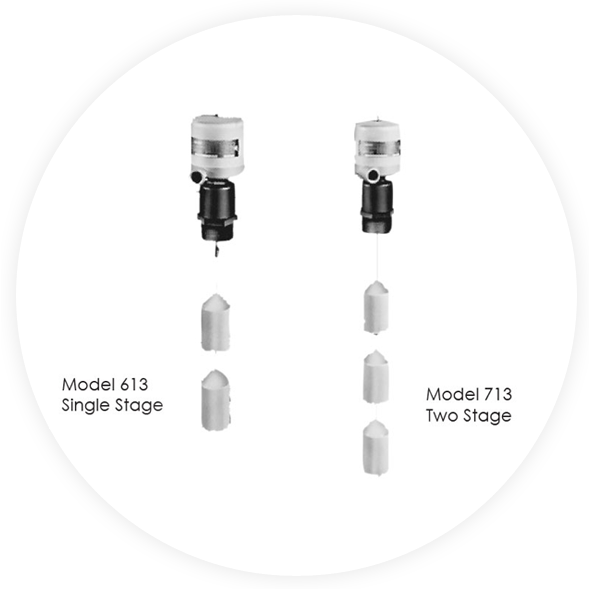

The Omnitrol 613/713 Series with porcelain displacers offers proven magnetic displacer switching, exceptional chemical resistance, and safe operation in hazardous areas.

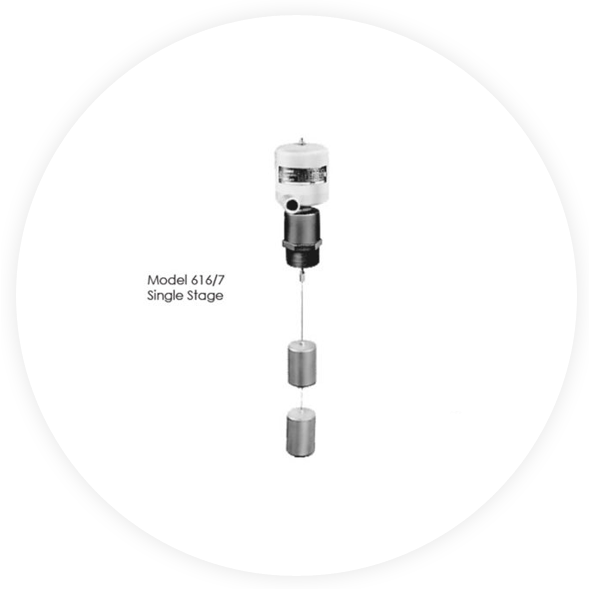

The Omnitrols 616 and 716 Top Mounted Level Control Switches are robust, stainless steel displacer-actuated devices giving for long service life with corrosive, hazardous, or high-value products.

The Omnitrol 621/721 Series delivers level switching using dense lead displacers to deliver reliable high-level and overfill protection on floating-roof storage tanks.

Omnitrol displacer switches combine buoyancy-based sensing with a magnetic snap-action mechanism:

The result is accurate, vibration-proof switching without any process penetration or moving linkages between the liquid and switch housing.

Displacer switches are most effective in liquid level detection and control for:

Refineries, chemical plants, and storage terminals — for high or low-level alarms, pump protection, and overfill prevention.

Pressurized or closed vessels — where side access isn’t possible or chamber installation is impractical.

Boilers and condensate systems — for high-temperature service where floats or electronics may fail.

Wastewater and sump applications — where turbulence, foam, or coating media can interfere with float or ultrasonic devices.

Floating roof and API 2350-compliant overfill systems — using dense displacers for accurate roof-height alarms.

Typical process conditions include pressures up to 1500 psig and temperatures to 500°F, with materials of construction such as stainless steel, graphite, porcelain, or lead, selected for compatibility and durability.

Use displacer-based switches when you need:

Compared to other L&J Technologies portfolio options:

Omnitrol’s top-mounted and chamber-mounted switch designs have been proven for decades in process industries. Their magnetically coupled actuation, rugged isolation tube construction, and choice of displacer materials ensure dependable service across a wide range of applications.

Displacer switch technology provides a robust, power-free solution for critical level control in demanding process environments.

Omnitrol’s top- and chamber-mounted displacer switches combine the mechanical simplicity of buoyancy operation with the precision and safety of magnetic switching, delivering reliable performance where electronic or float-based devices fall short.

Whether installed on refineries, chemical plants, or storage terminals, Omnitrol displacer switches offer peace of mind — delivering accurate, repeatable control and long-term durability in the toughest conditions.