Choose the MCG 3210i to power, isolate, and manage large groups of L&J field devices, improving data security, surge protection, and system reliability across multiple tank fields.

Choose the MCG 3221 to seamlessly connect L&J Tankway field devices to Modbus-based PLCs or DCS systems, enabling bi-directional data exchange without modifying existing control architectures.

Choose the MCG 820063 IFIC to upgrade existing field interface racks with intelligent diagnostics, selectable voltage and current, and real-time visibility into field wiring health and device performance.

Choose the MCG 3281 when you need a compact, cost-effective way to connect a small number of L&J Tankway devices to a host system with full diagnostics and configuration access.

Choose the 8810 RTU for scalable, Ethernet-based integration of hundreds of tanks and mixed-protocol devices, delivering high-speed data, advanced diagnostics, and secure OPC UA connectivity.

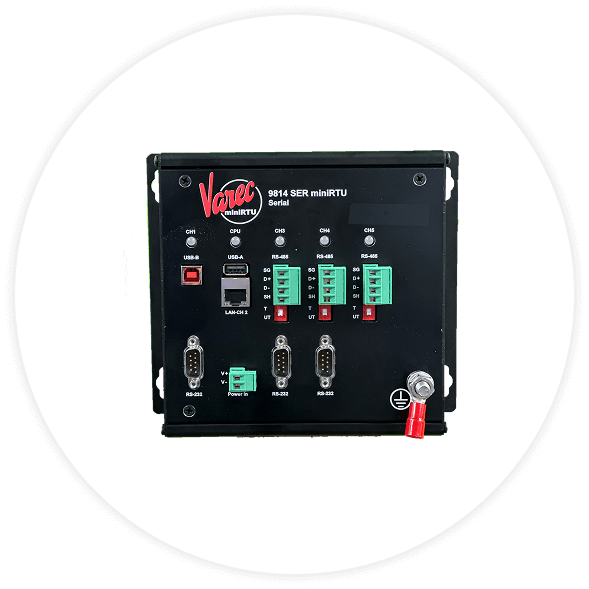

Choose the 9810 miniRTU for cost-effective data collection from small to mid-sized tank farms, consolidating multiple gauges into a single Ethernet or Modbus interface with modern protocol support.

Users choose the MCG 3905 for accurate, real-time visibility into tank inventories across complex facilities.

Tank farm and terminal inventory systems requiring centralized collection of level, temperature, and alarm data from large numbers of tanks.

Remote or unattended facilities where RTUs provide reliable data acquisition and limited control without continuous operator presence.

SCADA and stand-alone control applications that require deterministic data polling, local buffering, and alarm handling.

Modernization and retrofit projects where legacy gauge protocols must be preserved while new instruments and host systems are introduced.

Multi-vendor environments where a single interface layer simplifies integration across different manufacturers’ tank gauges and transmitters.

High-capacity RTUs in this layer are designed to scale well beyond a handful of tanks, supporting hundreds of tank connections, multiple host ports, redundant power inputs, and secure Ethernet communications to ensure long-term system viability.