View Products:

For operators who want reliable digital level, temperature, and alarm data while preserving the simplicity, durability, and proven performance of their existing mechanical gauges.

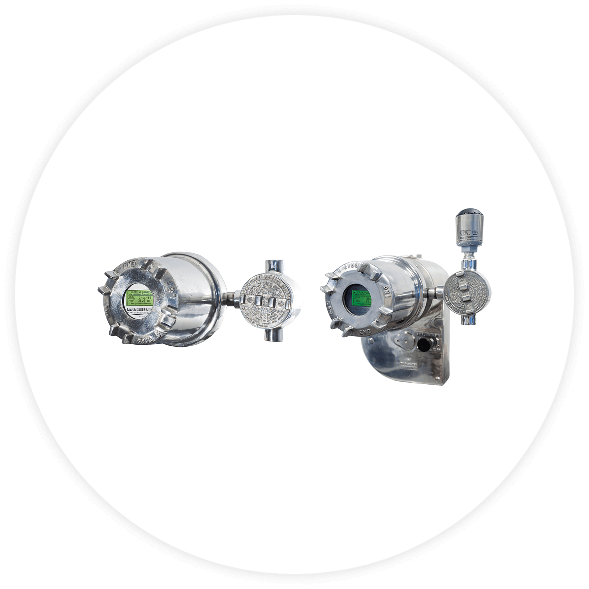

Choose the MCG 1200M to convert analog level, temperature, pressure, or BS&W signals into digital tank-gauging protocols, delivering flexible integration, local display, and safe infrared configuration in hazardous areas.

For terminal operators, field engineers, plant supervisors, inventory managers, and safety officers who need safe, ground-level access...

Adding a transmitter transforms a local measurement into actionable information. Operators gain real-time visibility, engineers gain reliable data for automation and reporting, and safety systems gain dependable signals for alarms and shutdown logic. Without a transmitter, critical tank information remains isolated at the gauge.